STANDARD

ANSI/ISEA 105-2016

American National Standard for Performance and Classification for Abrasion Resistant Gloves

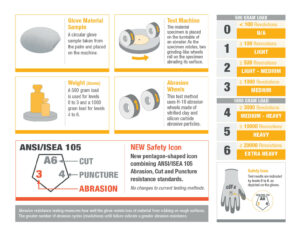

ANSI/ISEA 105-2016 establishes performance levels, testing and classification for gloves designed to provide abrasion resistance while performing occupational tasks.

The standard, based on ASTM D3389-10 (coated glove fabrics or unsupported gloves) and ASTM D3884-09 (uncoated glove fabrics), tests the glove’s abrasion resistance by determining the number of revolutions (abrasion cycles) to failure. The test method uses a 4-inch circular sample (cut from the palm) mounted on a horizontal axis platform while being abraded to failure under a specified vertical weight load (500 or 1000 grams) by the sliding rotation of two vertically oriented H-18 abrading wheels comprised of vitrified clay and silicon carbide abrasive particles. The results, recorded in revolutions, are represented by levels 0 to 6, with the greater number being the higher level of abrasion resistance.

Abrasion resistance testing measures how well the glove resists loss of material from rubbing on rough surfaces. The greater number of abrasion cycles (revolutions) until failure indicate a greater abrasion resistance.

For the latest safety standards, classifications, testing criteria and ratings information, please refer to the appropriate governing body or association. Information contained in this document is subject to change without notice. As BDG® cannot control or anticipate the conditions under which a product may be used, each user should review the information in specific context of the planned use. To the maximum extent permitted by law, Bob Dale Gloves and Imports Ltd., and/or its affiliates, employees or representatives will not be responsible for damages of any nature resulting from the use or reliance upon the information contained in this sheet. No express or implied warranties are given other than those implied mandatory by law. BDG® products are not cut and puncture proof. Do not use with moving blades, tools or serrated blades.