STANDARD

EN 407:2020

European Standard for Protective Gloves Against Thermal Risks (Heat and/or Fire)

EN 407:2020 establishes thermal performance levels, testing and classification for protective gloves and other hand protective equipment for professional, consumer or domestic use against heat and/or fire.

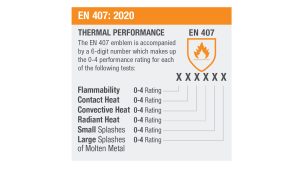

This standard is comprised of six separate thermal tests—burning behavior, contact heat, convective heat, radiant heat, small splashes of molten metal, and large splashes of molten metal. Each test is rated from 0 to 4, with 4 offering the greatest degree of protection. A zero (0) rating means no rating was earned.

Resistance to Flammability

Two whole gloves are stretched and exposed to a gas flame, one for 3 seconds and the other for 15 seconds. After the gas flame is extinguished, the length of time is measured for how long the material continues to burn or glow. The gloves are also inspected for damage to the materials and seams.

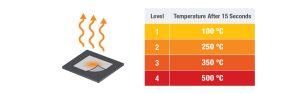

Resistance to Contact Heat

Samples of the glove’s palm material are placed on four plates ranging in temperature from 100 – 500°C. Time is measured to determine how long it takes the temperature of opposite side of the material to increase by 10°C from an initial temperature of about 25°C. A minimum time of at least 15 seconds is required to pass each level.

Note: EN 407-rated gloves must achieve a minimum 10 N tear resistance (Level 1 requirement of EN 388) to be certified to EN 407:2020.

Resistance to Convective Heat

In this test, samples of the glove’s cuff, back and palm are exposed to a gas flame. The time is measured to determine how long it takes to increase the temperature of the glove’s inner material by 24°C.

Resistance to Radiant Heat

Samples of the glove material is stretched in front of a radiant heat source. The time is measured to determine how long it takes to increase the temperature of the glove’s inner material by 24°C.

Small Splashes of Molten Metal

The test measures the number of molten metal drops (0.5 g) on material samples, taken from the glove back and palm, that are needed to raise the temperature by 40°C on the opposite side of the sample.

Large Splashes of Molten Metal

Molten metal is poured over the glove material to determine the total weight of molten iron needed to damage simulated skin (PVC foil) placed underneath the glove material.

For the latest safety standards, classifications, testing criteria and ratings information, please refer to the appropriate governing body or association. Information contained in this document is subject to change without notice. As BDG® cannot control or anticipate the conditions under which a product may be used, each user should review the information in specific context of the planned use. To the maximum extent permitted by law, Bob Dale Gloves and Imports Ltd., and/or its affiliates, employees or representatives will not be responsible for damages of any nature resulting from the use or reliance upon the information contained in this sheet. No express or implied warranties are given other than those implied mandatory by law. BDG® products are not cut and puncture proof. Do not use with moving blades, tools or serrated blades.