STANDARD

FDA 21 CFR 177.2600

US Food and Drug Administration Standard for Food Additives

FDA 21 CFR 177.2600 is the U.S. Food & Drug Administration (FDA) regulation that covers the use of rubber articles (gloves) that may be safely used in producing, manufacturing, packing, processing, preparing, treating, packaging, transporting, or holding food.

The FDA requires that all food handling gloves must meet FDA Title 21 CFR Part 177, which necessitates that gloves must be both sanitary and impermeable. In accordance with FDA regulations, gloves used in food service and food processing must comply with 21 CFR 177 parts 170-199, which specifies the requirement for items that are in repeated contact with food items and that are otherwise evaluated against indirect food additive regulations.

Indirect food additives are substances that come into contact with food but are not intended to be added to food. These additives can come from anything that food comes in contact with, including equipment, packaging, workwear, and personal protective equipment (PPE) such as work gloves.

FDA 21 CFR 177.2600 as it Pertains to Work Gloves

- FDA 21 CFR 177.2600 includes a list of permitted base elastomers, vulcanization materials, accelerators, retarders, activators, antioxidants, plasticizers, fillers, emulsifiers, and other additives used in the manufacture of work gloves for food handling. The list recognizes some materials as inherently safe, these are classified as GRAS, generally recognized as safe.

- FDA 21 CFR 177.2600 also stipulates that rubber products intended for repeated use in contact with food should be thoroughly cleansed prior to their first contact with food, and includes a list of materials and chemicals permitted to come in contact with food. Approved substances include acrylonitrile-butadiene copolymer (Buna), silicone, polytetrafluoroethylene, and ethylene propylene diene monomer.

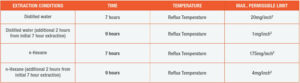

- FDA 21 CFR 177.2600 sets the product extraction limits for both aqueous and fatty foods. Extractables in fatty foods must be less than 20 milligrams/square inch after the sample is refluxed with hexane for seven hours and then just 1 mg/square inch for the next 2 hours. For aqueous foods, the criteria is 175 mg/square inch of extractables when refluxed with water for 7 hours and 3 mg/square inch for the next 2. The testing is pass/fail.

Single and Multi-Use Work Gloves

The FDA food code recognizes that various grades of work gloves are available for use by food facilities and classifies them as either single-use gloves or multiple-use gloves. This distinction is based on each glove type’s durability, strength, and cleanability.

Multiple-use gloves are durable, non-absorbent, and resistant to corrosive food facility sanitizers. These gloves can withstand repeated washing and disinfecting treatments without being damaged or decomposing. Both multi- and single-use glove types must be safe for food contact, meaning there can be no migration of substances, colours, odours, or tastes from or through the glove to the food being handled.

For the latest safety standards, classifications, testing criteria and ratings information, please refer to the appropriate governing body or association. Information contained in this document is subject to change without notice. As BDG® cannot control or anticipate the conditions under which a product may be used, each user should review the information in specific context of the planned use. To the maximum extent permitted by law, Bob Dale Gloves and Imports Ltd., and/or its affiliates, employees or representatives will not be responsible for damages of any nature resulting from the use or reliance upon the information contained in this sheet. No express or implied warranties are given other than those implied mandatory by law. BDG® products are not cut and puncture proof. Do not use with moving blades, tools or serrated blades.