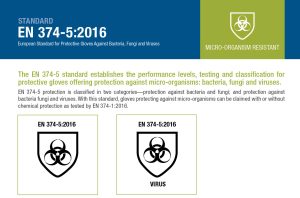

STANDARD

EN 374-5:2016

European Standard for Protective Gloves Against Bacteria, Fungi and Viruses

The EN 374-5 standard establishes the performance levels, testing and classification for protective gloves offering protection against micro-organisms: bacteria, fungi and viruses.

EN 374-5 protection is classified in two categories—protection against bacteria and fungi; and protection against bacteria fungi and viruses. With this standard, gloves protecting against micro-organisms can be claimed with or without chemical protection as tested by EN 374-1:2016.

Penetration

All gloves claiming micro-organism protection must be penetration tested and inspected in compliance with the EN 374-2:2013 standard for air leaks and water leaks. Penetration is the movement of a chemical and/or micro-organism through porous materials, seams, pinholes, or other imperfections in a protective glove material at a non-molecular level. Testing measures the time taken for a chemical to break through the glove material and come into contact with the skin. The detection of any leakage when undergoing the air and water leak testing constitutes a failure.

Protection against bacteria and fungi

Gloves claiming protection from bacteria and fungi must carry the following warnings:

• The penetration resistance has been assessed under laboratory conditions and relates only to the tested specimen.

• Not tested against viruses.

Protection against bacteria, fungi and viruses

Gloves claiming protection from bacteria, fungi and viruses must carry the following warning:

• The penetration resistance has been assessed under laboratory conditions and relates only to the tested specimen.

To offer protection against bacteria, fungi and viruses, the glove must be tested to ISO 16604:2004 (Method B) for protection against contact with blood and body fluids. Using the bacteriophage penetration test for blood-borne pathogens, a nutrient broth containing a virus is forced against the glove for a specified time and pressure pattern. The detection of any permeation constitutes a failure. For gloves longer than 400 mm, and if the cuff is claimed to protect against micro-organisms, an additional test specimen will be taken from the cuff area and tested to ISO 16604:2004.

For the latest safety standards, classifications, testing criteria and ratings information, please refer to the appropriate governing body or association. Information contained in this document is subject to change without notice. As BDG® cannot control or anticipate the conditions under which a product may be used, each user should review the information in specific context of the planned use. To the maximum extent permitted by law, Bob Dale Gloves and Imports Ltd., and/or its affiliates, employees or representatives will not be responsible for damages of any nature resulting from the use or reliance upon the information contained in this sheet. No express or implied warranties are given other than those implied mandatory by law. BDG® products are not cut and puncture proof. Do not use with moving blades, tools or serrated blades.