STANDARD

EN 511:2006

European Standard for Protective Gloves Giving Protection from Cold

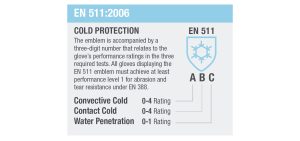

EN 511:2006 is the standard that gloves must meet to offer protection against convective cold, contact cold, and water permeability.

The standard specifies the requirements and test methods that glove manufacturers test for A) Resistance to Convective Cold, B) Resistance to Contact Cold, and C) Permeability by Water.

Resistance to Convective Cold

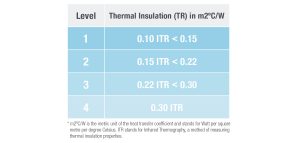

This test determines how well the glove protects against convective cold based on the insulating properties of the glove, which are obtained by measuring the transfer of cold via convection. In a controlled environmental chamber, the glove is placed on a model hand and heated to around body temperature (30-35°C). The chamber is cooled to 20°C below that of the heated hand with constant air flow applied. The electrical power needed to maintain a constant temperature between the surface of the heating hand and the chamber temperature is measured. The greater the electrical energy used indicates lower levels of thermal insulation. The protection level is indicated by a number between 1 and 4, where 4 indicates the strongest level of resistance to convective cold.

Resistance to Contact Cold

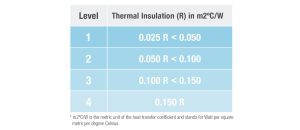

This test shows how well the glove protects against contact cold based on the thermal resistance of the glove material when exposed to contact with a cold object. A piece of glove material from the palm side is placed between a warm plate that is heated to around body temperature (30-35°C) and a cold metal plate. An extractor fan is used to cool down both plates and after 30 minutes the measured drop in temperature across the inner and outer surface of the sample is used to calculate the glove’s thermal resistance to contact cold. The protection level is indicated by a number between 1 and 4, where 4 indicates the strongest resistance to contact cold.

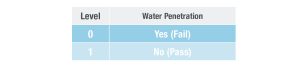

Permeability by Water

The third test shows the glove protection against water penetration. The glove is fully submerged in water for 30 minutes. If no water penetration is realized, the glove passes and gets a 1 rating. If any water passes through to the inside the glove it is considered a fail and receives a 0 rating.

For the latest safety standards, classifications, testing criteria and ratings information, please refer to the appropriate governing body or association. Information contained in this document is subject to change without notice. As BDG® cannot control or anticipate the conditions under which a product may be used, each user should review the information in specific context of the planned use. To the maximum extent permitted by law, Bob Dale Gloves and Imports Ltd., and/or its affiliates, employees or representatives will not be responsible for damages of any nature resulting from the use or reliance upon the information contained in this sheet. No express or implied warranties are given other than those implied mandatory by law. BDG® products are not cut and puncture proof. Do not use with moving blades, tools or serrated blades.